Author: Shri Amit Kumar, Editor-in-Chief, Sea and Coast

Change is the constant partner of a civilization. When a sector like shipping has the responsibility of maintaining a global supply chain on its shoulders, changes are inevitably induced. But when we talk of shipping as a sector evaluating modern techniques, we can say that the changes- vivid Artificial Intelligence modules- are need-inducing. The shipping freight corridor now doesn’t come with ‘moving cargoes from one part to the other’ as the sole objective but bringing sustainability, efficiency, and environment-friendliness in the maritime shipping is of prime concern now.

However, the stress on making the shipping industry greener has been rightly addressed by the International Maritime Organisation, shipping giants, and research bodies. Releasing approximately 950 million tonnes of CO2, shipping contributes to nearly 3% of the global GHG emissions as reported by the 3rd IMO GHG study.

IMO bringing decarbonization in focus has built up the initial GHG strategy that aims at a reduction in the carbon intensity of international shipping (to reduce CO2 emissions per transport work, as an average across international shipping, by at least 40% by 2030, pursuing efforts towards 70% by 2050, compared to 2008); and that total annual GHG emissions from international shipping should be reduced by at least 50% by 2050 compared to 2008.

The need for developing and introducing more feasible pathways to ship things is the father of innovation and has skyrocketed the interference of Artificial Intelligence in the maritime industry. There are various AI-based modules that are pushing the maritime sector to the cusp of a new era. To name the biggest of them- Smart ships bringing economical efficiency via fuel optimization, route forecasting ensuring safe operations with better turn-around time, enhanced crane operations escalating port efficiency, drones navigating on the seas to deliver key spare parts, autonomous shipping, and digital twin paving the way for revolutionizing every single component from designing a ship to dismantling the same at the scrapyard.

Let us discuss these godfathers to greener and sustainable shipping in a more insightful manner.

Digital Twin

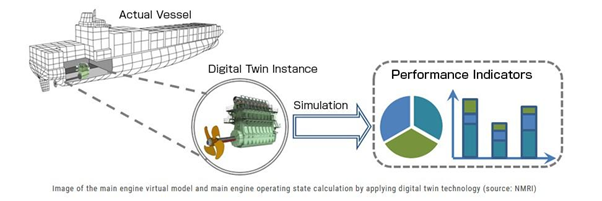

As defined by Glaessgen and Stargel, a digital twin is a multi-physics, multi-scale, and probabilistic simulation of a complex product that uses models, sensor updates, etc. to mirror the life of its corresponding physical twin. However, when we restrict the definition to the maritime domain, it says- digital twin is a virtual representation of a physical asset that renders its behavior and state close to real-time, sensor observations acting as the key to providing operational conditions. The basic architecture of digital twin looks like this:

- Physical Twin- Physical Asset+ acctutaors+ sensors

- Local Data source- Sensor interface on the physical twin

- Local Data RePOSITORIES- Data Servers and Local Databases located near the digital twin.

- IoT Gateway- Furnishes interfacing between local and cloud data repositories that establishes a connection between the physical twin and its virtual/digital counterpart.

- Cloud-Based information Repositories- Stores the data collected by physical assets and their digital counterpart

- Emulation and Simulation Platform- Generates value (predictive maintenance, optimization, etc.) through encompassed software with the help of gathered data.

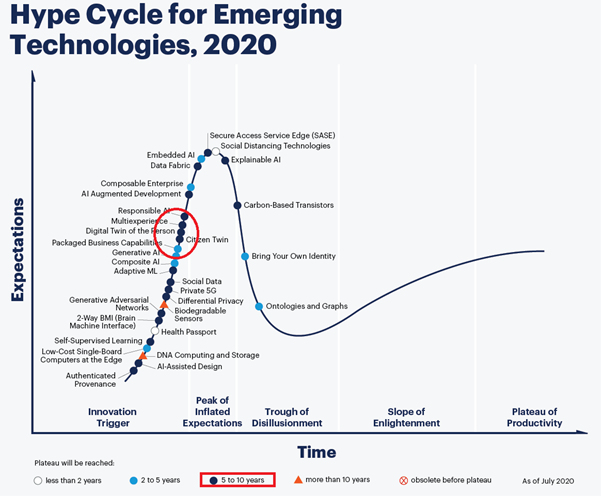

When we look into the Hype Cycle for emerging technologies graph for the year, it has been speculated that the digital twin technology is to reach the plateau of productivity in the time span of 5-10 years.

Port of Antwerp- the second largest port of Europe is the forerunner of digital twin technology. With different sensors- 500 cameras, pipeline information,12 different databases that include financial information, GIS Information, depth information, machine vision, Waterways available, shipping companies, and ships that are transporting cargo, the port of Antwerp has been successful in creating super situational awareness of the port. Port of Antwerp is rightly assisted by its port city that has a digital twin enabling better decisions on mobility, air quality, noise pollution, etc.

Shipyard with digital twin technology is also a reality today. Newport News Shipbuilding- America’s oldest and largest naval shipbuilder, sole-developer OF US NAVY war carriers- launched to steer the production of Ford Class the digital shipyard back in 2017 which aims at creating a digital twin of their entire shipyard.

Siemens NX Design supports the representation of the digital twin, and Team Centre serves as their information control system. It has introduced laser scanning to facilitate digital blueprints, cutting time as high as 6 months from 3 years of overhaul, augmented reality that facilitates ‘walkthrough’ and looks for apt maintenance room, modeling and simulation to get through operational dynamics and instill real-time problems solving in the design and process, and additive manufacturing to eradicate the need of carrying spare parts into processes to increase efficiency, safety, and affordability.

This methodology of the production line is surely a way to better efficient ships built through real-time operational dynamics before the ship touches water.

We’re seeing over 20 percent improvement in performance,” Chris Miner, vice president of in-service carriers at Newport News Shipbuilding commented. As reported by John Ord, Director of Technology Business Management, that integrated digital shipbuilding could cut 15% cost on third- Ford-class aircraft carrier. It was reported that Newport News Shipbuilding used TBM to boost transformation spending from 5% to 24% since 2016.

Adding to the hubbub around the digital twin technology, DNV GL has also joined hands with various stakeholders has developed a strategy for hull condition monitoring utilizing ship twin. With the aid of sensors that easily identify physical effects such as deformation, vibration, or temperature under real-world conditions and its Veracity module- DNV GL provides a quality assurance app for hull monitoring.

The other major projects in this domain are the digital twin of a cooling system by the Integrated Energy Solutions to Smart and Green Shipping (INTENS) project and Lappeenranta University of Technology (LUT), SINTEF, DNV-GL, and Kongsberg’s Digital Shipyard, and Mitsui O.S.K. Lines (MOL)- digital twin of the main engine project being developed in collaboration with National Institute of Maritime, Port, and Aviation Technology (MPAT), and National Maritime Research Institute (NMRI).

AI Enhanced Crane Operations

Terminal operations and stowage plan verily impact port efficiency, vessel turnaround time, and timely cargo delivery. Cargoes need to be loaded and unloaded for which industrial cranes are deployed. Moving tonnage of cargoes amid gust of wind on a port could hamper the structural integrity and result in catastrophic accidents.

With the help of cameras, actuators, anemometer, sensors measuring torque of the structure, sensors measuring meteorological parameter; Artificial intelligence and machine learning for both automated container port management and trucks and ships are already in use or under development in a few key ways officials to ensure efficient operations and predict failure before they happen via monitoring the situations. AI already is in use in automated loading cranes at ports in southern California, New Jersey, and Virginia in the United States; Shanghai in China, and Rotterdam in the Netherlands. The AI makes decisions about which containers to stack or unload first based on a database and other analyses.

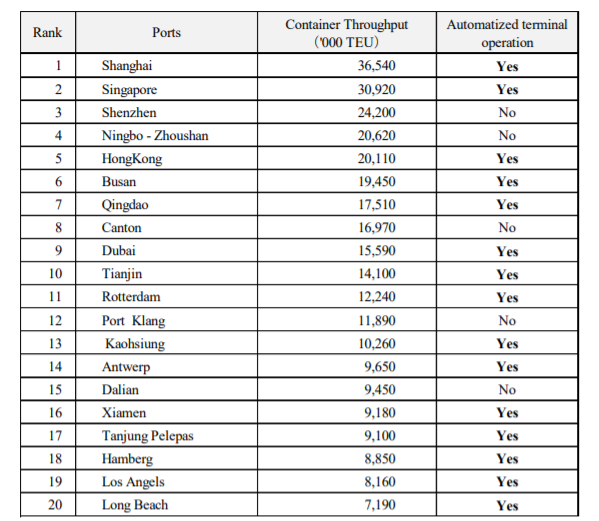

Among the top twenty container hub ports, fifteen have had or will soon have at least partially automatized one or more terminals, as per a 2018 report.

When it comes to shipping cargoes amid wind gusts, high seas- safety plays a vital role. Route Forecasting not only employs economical feasibility to the trade but also imparts security to the ship and its crew members. Route forecasting optimizes the best route taking storms, downpours, heavy underwater current, and high waves into account. This is not something new as there have been plenty of projects where shipping giants had invested, some in the process of developing, some using the technique, and some to join the list soon. Back in 2015, Power and automation group ABB and dutch weather forecasting specialist MeteoGroup bagged an order of outfitting 140 containers with software to optimize routes. However, the top maritime route forecasting software enlists “Navi-Planner” of Tranzas, “PassageManager” of ChartCo, “Bon Voyage System” of StormGeo, “Ship Performance Optimization” System” of MeteoGroup, “Commercial Marine Vessel Routing” of Jeppesen, Navtor.

Vessel Performance and Fuel Optimization

Leveraging AI and Machine Learning, an optimal route is planned for the vessel analyzing the dimension, properties, optimum, and weather conditions. This optimal route provides a more efficient functioning of the vessel by reducing the fuel consumption by 2-10%.

Swedish ferry operator Stena Line successfully piloted the project through a software named Stena Fuel Pilot in 2018 onboard Stena’s Scandinavica vessel on the Gothenburg – Kiel route. The project conclusively showcased that it helped in cutting fuel consumption by 2-3%. Thereafter, Stena Line went on to retrofitting its 37 vessels with the system in Europe by late 2020.

AI is not only limited to Fuel Optimization but also contributes to detailed remote inspection and maintenance onboard through predictive maintenance- enabling the early detection of equipment failures before they happen. Remote inspection through Video conference, image recognition system, NDT methods, sound recognition system help ship owners, vessel managers to maintain the health of ships and increase the lifetime of ships.

In 2018, Maersk announced the launch of Captain Peter, an AI virtual assistant to help customers remotely manage their containers and gain greater insight into their cargo’s voyage.

AI-enabled Image Recognition and Sound recognition also facilitates the detection of hazards in the way of navigation and ensures more dependability on the route and safe navigation.

Drone Delivery

Drone delivery has been introduced to ships and on ports to deliver essential spare parts, necessary medications, and other essentials without any intervention of human interaction and touch increasing the risk and exposure to the coronavirus. Not only limited to deliver supplies but drones can also be used for infrastructure surveillance at ports and shipment areas, to see the proper execution of safe distancing mandates and thermal imaging of the personnel and report any variability indicating Corona Virus. Terra Drone is using its drones to supply medical and quarantine supplies with the least amount of risk Xinchang County’s disease control center and the People’s Hospital in China. A start-up named F Drones has done the first commercial authorized beyond-visual-line-of-sight BVLOS drone delivery to ships in Singapore where it delivered 2 kg of vitamins over 3 km approximately in 7 minutes to a ship operated by Eastern Pacific Shipping. “These traditional means of transport are expensive, slow, labor, and carbon-intensive. F-drones’ solutions can help save up to 80% of the costs, time, and CO2 emissions. F Drones made the first commercial drone delivery at night on 1 November 2020 delivering the world’s first 3D printed CE-certified Lifting Tool from #Wärtsilä, sent in partnership with #WilhelmsenGroup weighing 3 kilograms over 5 kilometers within 7 minutes to Berge Sarstein, owned by Berge Bulk.

Besides being efficient, delivery drones can also reduce unnecessary human contact amid the COVID-19 pandemic,” says Nicolas Ang, CEO of F-drones. Drones aided with bots with UVC Lights aided with programmed AI can also be used for sterilization and disinfecting purposes without human contact. The concept of Urban Air mobility is a very good alternative to the traditional method of delivering goods in an era where the world is hit by pollution, traffic congestion, and urgency to follow safe distancing and avoid human contact.

Conclusion

The environmental urge to make the maritime industry and shipping more eco-friendly and build a more sustainable, efficient, and greener supply chain has pushed innovation and new technologies in shipping. Undoubtedly, these technologies are on the verge to be accepted across the maritime ventures heavily and have surely pushed the Maritime industry to the cusp of the new era.

Note: Shri Amit Kumar is the Chief Editor and Director of Sea and Coast. The article has been published un-edited and all content and accuracy rests with the author.